The Ultimate Beginner's Guide to DTF Printing: From Zero to Expert

DTF printing (Direct-to-Film printing) is revolutionizing the custom apparel industry with its vibrant colors, ease of use, and compatibility with diverse fabrics. Whether you're a DIY enthusiast or entering the world of personalized clothing, this guide will help you start from scratch and master the essentials of DTF printing.

1. What is DTF Printing? Unleashing Creativity with Ease

So, what is DTF printing? It's a cutting-edge digital technology that transfers designs directly onto fabrics. Unlike traditional methods requiring extensive setup, DTF printing allows you to print your design directly onto PET films. Once printed, a layer of adhesive powder is applied, and the design is transferred to the fabric using a heat press. This versatile process is ideal for small batches and personalized designs.

Key Advantages:

No need for screen setup: Save time and effort.

Cost-effective for small runs: Perfect for startups and small businesses.

Vivid and durable prints: Your designs will stand out and last longer.

2. Essential Tools and Supplies for DTF Printing

Having the right tools and supplies is critical to your success in DTF printing. Here's a list of what you'll need:

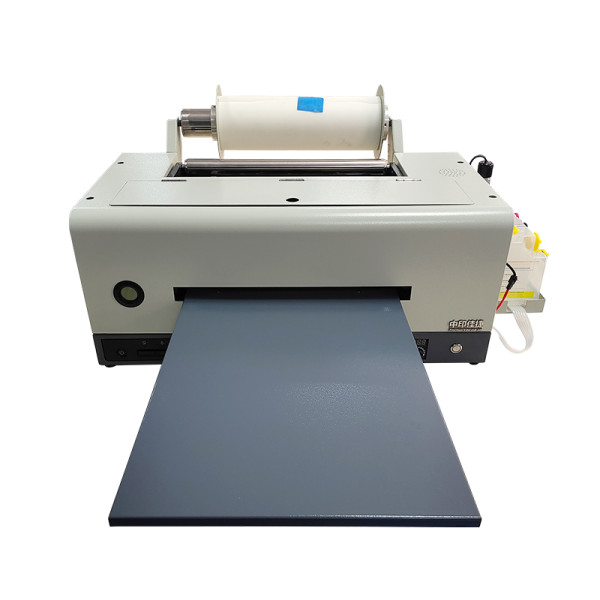

DTF Printer: This is the cornerstone of your setup. If you're a beginner, choose a DTF printer for beginners that's easy to use and offers stable performance. Professional DTF printing machines are available for more advanced users.

DTF Ink: High-quality ink ensures vibrant, long-lasting prints. Always choose ink compatible with your printer for smooth transitions and optimal adhesion.

PET Film: The medium on which you'll print your designs. Opt for smooth, consistent PET films to avoid streaks or smudges.

Adhesive Powder: This heat-activated powder bonds your design to the fabric. Choose the appropriate grade based on the material and its washing requirements.

Heat Press Machine: A must-have for transferring your design to fabric and ensuring durability.

Powder Shaker (optional): Distributes adhesive powder evenly, improving quality and reducing waste.

Dryer or Oven: Cures the adhesive powder, preparing the design for transfer.

3. The DTF Printing Process: A Step-by-Step Guide

The DTF printing process is simple and beginner-friendly. Follow these steps to get started:

Design Your Artwork: Use graphic design software to create or customize your design.

Print Your Design: Load the PET film into your DTF printer and print the design in a mirror image.

Apply Adhesive Powder: Sprinkle adhesive powder evenly over the printed design. A powder shaker can simplify this step.

Cure the Design: Use a dryer or oven to melt the adhesive powder, bonding it to the ink.

Transfer to Fabric: Place the cured film on the fabric and use a heat press to transfer the design. Follow the recommended time, temperature, and pressure settings.

Peel and Reveal: Once cooled, peel off the film to reveal your durable, vibrant print.

4. Tips for Choosing a Trusted DTF Partner

Finding a reliable partner for your DTF printing machine and supplies is crucial. Fcolor is a trusted name, that offers everything you need for a smooth printing experience. Here's why they're an excellent choice:

Quality Assured: High-quality printers, inks, and consumables ensure professional results.

Expert Support: Their team provides excellent customer service to resolve any issues you may encounter.

Comprehensive Solutions: They offer a full range of products, from entry-level DTF printers to advanced equipment.

Fast Shipping: With U.S.-based warehouses, they provide swift delivery for North American customers.

5. Pro Tips for Achieving Outstanding Results

To take your DTF printing to the next level, keep these expert tips in mind:

Fine-Tune Printer Settings: Adjust ink density and resolution based on your design and fabric type.

Maintain a Clean Workspace: Dust or dirt can interfere with print quality and adhesion.

Regular Maintenance: Clean printheads and other components to ensure your printer operates efficiently.

Experiment with Fabrics: Test different materials to discover unique textures and effects.

6. Conclusion: Start Your DTF Printing Journey Today

DTF printing opens up endless possibilities for creative and commercial ventures. With the right tools and knowledge, even beginners can produce professional-grade results. Whether you're using a DTF printer for beginners or scaling up with a high-performance DTF printing machine, partnering with FCOLOR ensures you have the support and quality materials to succeed.

FCOLOR, a leading provider of custom inkjet printing solutions, offers a comprehensive range of printers, inks, and consumables. We specialize in developing and manufacturing high-quality inks, including dye, pigment, sublimation, eco-solvent, film, and DTF printer inks, tailored to meet diverse printing needs. Our product portfolio also encompasses a wide selection of inkjet printers, card printers, label printers, ink cartridges, PVC/ID cards, and other printing essentials. From dye sublimation to digital printing, FCOLOR empowers businesses with the tools and resources they need to achieve vibrant, professional results. Our expertise extends to custom ink formulations and printing systems, ensuring innovative and efficient solutions that enhance printing capabilities. With a steadfast commitment to quality and customer satisfaction, FCOLOR is your trusted partner for all your printing requirements.

Start your DTF printing journey today and turn your creative visions into stunning, wearable art. Contact us.

DTF printer High precision nozzle printing clearer image 60cm roll to roll direct to film printer

FCOLOR improved DTF inkjet digital printing printing, more complete features, more secure digital printer

MAX Print Size A3+ (13x19'' )

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer

MAX Print Size A3+ (13x19'' )

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer