Provide Heat Transfer, Sublimation, Direct Print, Faux Embroidery Digital Printing Solutions

What Digital Printing Solutions Do We Offer?

What is heat transfer printing?

Heat transfer printing is a digital printing method. The process involves transferring a design directly onto a special film or paper and then using a heat press to transfer the design onto the substrate. Heat transfer printing can be used on a variety of materials including polyester, denim, cotton, leather and nylon. The prints produced are favored for their cost-effectiveness and ability to produce high-resolution prints. In the print market, thermal transfer printing is categorized into various forms, the most common of which is DTF, which stands for the present.

What is the value of our heat transfer printing solutions?

Stable Use

Long-term maintenance of the equipment is included in our program. Any problems will be solved for you the same day so you don't have to worry about production!

Diversified Products

Not only do we provide you with a wide range of products, but we also help you to better synergize the operation of each product to increase operational efficiency.

Price Advantage

The device's ability to conserve supplies ensures you get more out of your projects. The quality of supplies themselves will further maximize your returns.

Heat transfer printing common applications

Shoe Printing

Hat Printing

Handbag Printing

What is sublimation printing?

Sublimation printing encompasses several different digital computer printing techniques that use heat to transfer dyes to the substrate. The most common sublimation printing process today uses standard inkjet printers to deposit ink with sublimation capabilities onto a transfer paper, and then heat is used to press the printed transfer paper against the substrate, transferring the dye to the substrate, such as plastic or fabric, through sublimation.

What is the value of our sublimation printing solutions?

High Return On Investment

Specially customized equipment allows you to increase production with low consumable consumption for a high rate of return.

Multimodule Advantage

You can customize the printing supporting module at will to solve all types of sublimation printing. Diversified molds allow you to cover business.

Flexible Supply

Supplies for all sublimation printing needs, from desktop to wide format. Fast turnaround and delivery right to your door.

Sublimation printing common applications

Apparel Printing

Phone Case Printing

Keychain Printing

Mousepad Printing

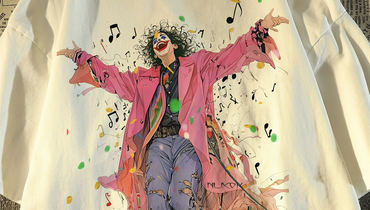

What is digital direct printing?

Digital direct printing is a process that uses direct inkjet methods onto a substrate. The most common process is DTG (Direct-to-Garment) printing, which uses specialized water-based inkjet technology to print on textiles. Compared to traditional printing methods such as screen printing, the prints are clearer and have a higher resolution (DPI). Unlike screen printing, DTG printing does not require lengthy setup or cleanup processes and can print a single shirt at a minimal cost.

What is the value of our digital direct printing solutions?

Special Customization

Solutions are available for printing on materials other than cotton and cotton blends, bringing more possibilities to your fabric printing.

Technical Support

Provide appropriate printing documents and technical support to improve equipment scheduling capabilities, enhance printing results.

Boutique Matching

Provides high-definition, high-color consumables that expand the fabric's color coverage and enhance pattern design effects.

Digital direct printing common applications

Garment Printing

Garment Printing

Garment Printing

Garment Printing

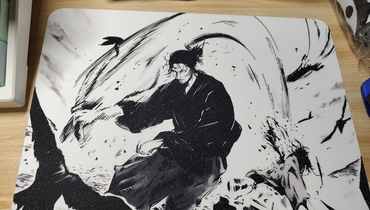

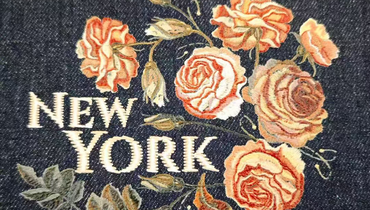

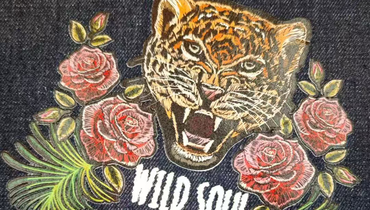

What is faux embroidery printing?

Faux embroidery printing is an embroidery digitizing printing process. It fundamentally solves the problem of integrating hand embroidery and digitized printing. It provides more possibilities for fabric garment type printing. Unlike normal stitching techniques which tend to produce a lot of leftover threads and fabric scraps, Faux Embroidery Printing reduces material waste, eliminates the need for excess material and saves up to 60% of the cost of hand embroidery overall. It gives the design a textured look like real embroidery.

What is the value of our faux embroidery printing solutions?

Design Support

Pattern design support is provided to help you optimize the content of your pattern design and enhance the realism of your printing results.

Printing Customization

Provide multi-printing process customization support. Printing can be realized on DTF, DTG, UV and other printing equipment.

Supplies Customization

We provide all the consumables used to achieve faux-embroidery effect printing, allowing you to precisely realize various effects.

Cooperation process

Faux Embroidery Printing

Faux Embroidery Printing

Faux Embroidery Printing

Faux Embroidery Printing

Our Heat Transfer Printing Solutions

DTF Printers For High-Volume Printing Operations

Can be integrated printing, powder handling (add and shake), drying in the integrated expansion design, easy to operate, from boot to print in two steps. Output is stable and high quality, help printing business growth.

Learn More

70CM Mesh Belt Powder Shaker

A press extension unit that combines powder addition, shaking and drying in one unit. Solves "redundant" steps such as manual powder shaking and film drying, and improves printing efficiency.

Learn More

Flatbed Heat Transfer Stamping Machine

Adopting high-precision heating plate, instant heating to realize transferring. Automatic memory temperature adjustment, "one point, one pressure" can be completed, refusing cumbersome operation.

Learn More

Customizable Sublimation Printing Solutions

Wide-Format Printing

Customizable printing surface, from fixed paper to any wide format, range size on demand. Customized heating and drying modules.

Learn More

Multi-Module Printing

Printing modules can be customized to fit a wide range of substrates, improving the ability to address the printing needs of various industries.

Learn More

Explore Garment Digital Direct Printing Solutions

Discover Our Unique Faux Embroidery Printing Solutions

Provides a solution to the problem of printing imitation hand embroidery designs. Restore fine designs while ensuring that image colors are vibrant and not too subtle.

Explore Supplies For All Your Digital Printing Needs

DTF Printer Ink: Multi-color options, precision color

Explore More

DTF PET Film: Customizable

Explore More

Hot Melt Powder: Very durable

Explore More

Faux Embroidery Ink: Aqueous, odorless, free-flowing, and non-clogging with a high color gamut

Explore More

Faux Embroidery Specialized Film: ABC three film set, multi-coating ink absorption, easy to peel

Explore More

Sublimation Ink: Multiple color options, true color display

Explore More

Sublimation Paper: 95% transfer

Explore More

Textile Ink: High fabric affinity

Explore MoreDigital Printing Industry Application Solutions

Textile Industry

Provides solutions for all applications related to apparel, shoes and hats. Involves 4 printing processes, simple to complex.

Promotional Goods Industry

The sublimation printing process, combined with multiple modules, can bring you more opportunities in promotional product sales.

What Services Will We Provide For This?

Free Program Consultation

Ask us about solutions online and we'll get back to you within 24 hours!

Equipment customization

Customized equipment to solve your printing needs and match productivity.

supplies customization

Customized supplies to solve your printing needs and match productivity.

Free sample production

We can create samples for you, or you're welcome to visit and see for yourself.

24/7 Pre-Sales support

Professional sales team 24 hours online to solve pre-sale doubts for you.

24/7 engineer support

24-hour online one-to-one guidance by professional engineers.

Contact Us To Enhance Your Digital Printing Business

Ask us any question about digital printing and we will provide you with the best solution

FAQ

- Q

Which industries can benefit the most from digital printing solutions?

- A

Solutions for the textile industry can benefit you more. The apparel category is the main focus, followed by other textile products such as shoes and hats.

- Q

How do I choose the right digital printing process for product needs?

- A

Different products have different printing solutions, the first thing we need to do is understand your product. Then we can recommend it for you.

- Q

Can digital printing handle a wide range of materials?

- A

It can be printed on common materials such as cotton, polyester fiber and PVC, but not all materials are suitable for printing.

- Q

How can I optimize it for specific application?

- A

We will optimize the printer equipment and printing process first, and then optimize the use of consumables.

- Name

- Tel

- *Title

- *Content