Home / All / DTF / DTF Printer /

FCOLOR Modified version XP600B DTF Printer | 60cm Printing Machine Manufacture

FCOLOR Modified version XP600B DTF Printer | 60cm Printing Machine Manufacture

| Categories | DTF Printer |

|---|---|

| Brand | Fcolor Printer Supplies Wholesale Manufacturer |

| Model | ZYJJ-XP600B |

| Print color | 6 colors |

| max print size | 24 inches(60cm) |

| Usage | print on pet film, then transfer on all fabric |

| Model | 24 inch pet film printer machine |

| Update Time | Apr 29,2025 |

Detail Information

60cm xp600B DTF printer One-stop solution

FCOLOR DTF XP600B Introduction of advantages

1. High cost performance:

XP600 nozzle is relatively cheap, can provide more stable performance, is a good choice for users with limited budgets.2. High resolution:

XP600 nozzle can provide high print resolution, good detail performance, suitable for printing images and delicate design.3. Suitable for a wide range of consumables:

suitable for a variety of types of ink and consumables, can be printed on a variety of materials of film, such as cotton, polyester, nylon and so on.4. High efficiency:

DTF printing is directly on the film, and then the image is transferred to the textile through thermal transfer technology, which has relatively high production efficiency and is suitable for small-batch customized production.5. Easy maintenance:

Compared with other industrial grade printhead, XP600 has low maintenance cost, easy to replace and repair, suitable for small businesses or personal use.FCOLOR DTF XP600 Printer Comparison of old and new

The appearance changes of DTF XP600

1. The appearance color collocation is more reasonable

2. The frame is changed to white for a more comfortable look

3. The front door is opened on both sides as a whole, no longer up and down

4. The paper platform is more beautiful

5. Open the cover as a whole, will not block the paper rod

6. The size of the new machine is larger

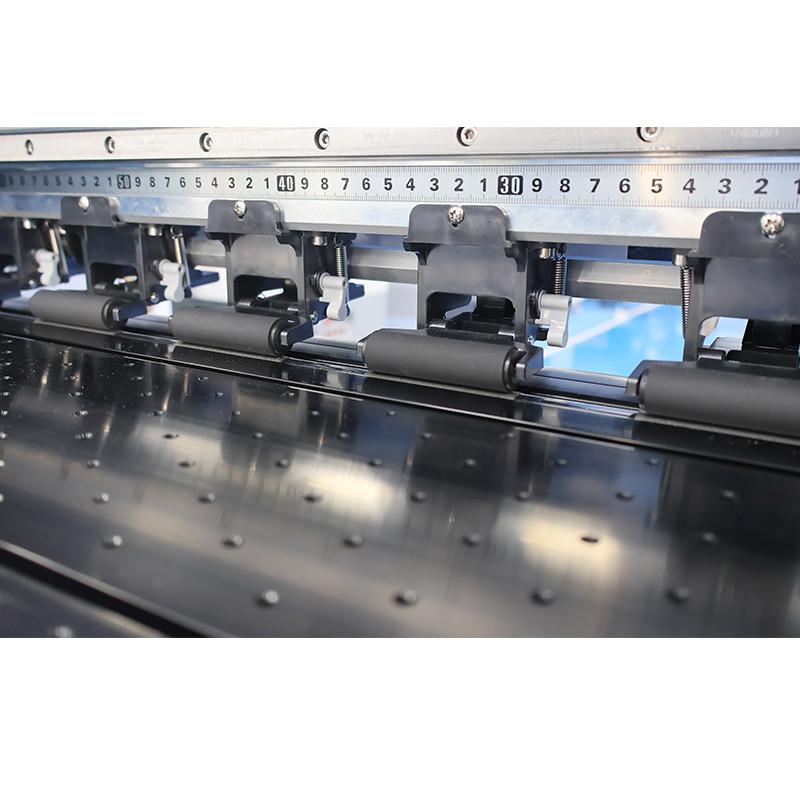

Structure Change of DTF XP600 Printer

1. Each part of the warehouse door has more Angle deflection protection and more convenient opening, the main part of the air vent area is larger, and the structure has more slots to put bottles

2. The paper wheel is larger, the roll shaft is longer, and there is a small flat section of pre-heating, which is a little prominent; Significant changes in the heating platform; Heating plate variation

3. The locks on both sides of the door are updated; The motherboard position can be simply opened, the rear motherboard has a cabinet door,

4. Fixed filter; The fixator is added, and the white ink reflux bottle is placed inside (which can be observed through the transparent plate); The back plate is transparent, the waste ink bottle is enlarged, the line protection is increased, and the ink sac protection is increased

5. Improved bottom pulley quality, updated with larger tires; Added foot cup, wheel brake; The whole support is strengthened and a fixator is added

The magic of DTF white ink mixer!

DTF white ink mixer plays an important role in DTF printing, mainly reflected in the following aspects:

1. Prevent precipitation:

white ink is easy to precipitate because it contains a large number of pigment particles. The mixer can effectively maintain the uniform distribution of white ink and avoid precipitating for a long time, thus affecting the print quality.2. Improve the printing effect:

by stirring to maintain the fluidity and uniformity of the white ink, the printed white base will be more stable and smooth, thus ensuring that the image color is more vivid and accurate, especially on dark or black materials.3. Extend the life of the nozzle:

white ink precipitation will block the nozzle, resulting in streaks or broken lines. Mixers reduce the risk of clogging, thereby extending the life of the nozzle, reducing cleaning frequency and reducing maintenance costs.4. Improve production efficiency:

The automatic mixing system can ensure that the state of the white ink is maintained at the best when working for a long time, without frequent suspension of the equipment to manually shake the ink bottle, thereby improving production efficiency.5. Reduce waste ink:

When the white ink is evenly mixed, the waste ink caused by precipitation or blockage will be reduced during the printing process, saving the cost of consumables.

Related Products

Review

- Loading...

Please send your message to us

- Name

- Tel

- *Title

- *Content

Please send your message to us

- Name

- Tel

- *Title

- *Content