- Printer

- Ink

- Consumables

- Type

- DTF Printer

- Sublimation Printer

- Eco-solvent printer

- Card printer

- label printer

- DTF oven

- DTF hot press machine

- Applicable ink

- DTF ink

- Sublimation ink

- Textile ink

- Dye ink

- Pigment ink

- Eco-solvent ink

- Color

- 4 colors

- 6 colors

- 8 colors

- 12 colors

- Ink properties

- DTF ink

- Sublimation ink

- Textile ink

- Dye ink

- Pigment ink

- UV ink

- Eco-solvent ink

- Capacity

- 70ML

- 100ML

- 500ML

- 1000ML

- 2000ML

- 25L

- Sales attribute

- Hot product

- New product

- Spot products

- OEM

- ODM

- Application Scenario

- Garment heat transfer printing

- Garment Sublimation Printing Printing

- Garment Direct Injection Printing

- Outdoor Advertising Printing

- Graphic and image printing

- Metal/Glass Printing

- label printing

- Card printing

- Other ink

- For people

- Clothing printing processing

- Physical advertising store

- Individual/Business/Government

- Photo studio

- Packaging and printing plant

- Hospital

- Printing house

- Packaging industry

- School library

- Mechanical printing plant

- Type

- DTF film

- DTF hot melt powder

- DTF hot melt powder

- Sublimation paper

- Washing fluid

- PVC card

- label paper

- Application field

- DTF printing field

- Sublimation printing field

- Card printing field

- Label printing field

Sublimation ink

Sublimation one-stop solution

What is the difference between DTF and thermal sublimation?

Sublimation

Thermal sublimation: The design is printed on thermal transfer paper and sublimates the ink to the surface of the item through high temperature and pressure, without additional shaking powder and heat curing steps. The ink goes directly from solid to gas, then back to solid and adsorbs on the surface, ensuring a strong bond and lasting pattern.

Transferable media: Fabrics other than pure cotton, suitable for smooth surface materials such as polyester, ceramics and metals. The ink is sublimed directly to the surface of the article through the thermal sublimation process, eliminating the need for primer and heat curing steps.

DTF

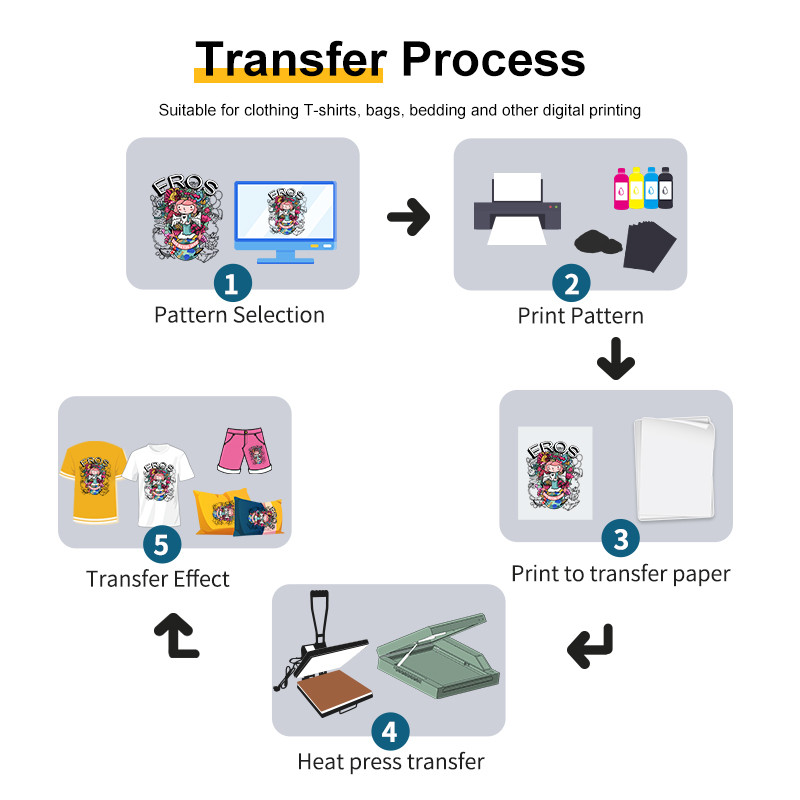

DTF: Using a DTF transfer film, you need to print the print pattern to the transfer film, and then print a layer of white ink, using hot melt powder and heat curing to complete the printing process. Finally, a heat transfer machine is needed to transfer the pattern to the clothes.

Transferable media: Suitable for all kinds of fabrics.

Market advantage of thermal sublimation

Thermal sublimation direct film forming (DTF) technology has been widely applied in printing and textile industry in recent years. Here are the main advantages of this type of technology:

High quality image: Sublimation DTF technology can produce high resolution and high quality images. Due to its fine color finishing and vivid color reproduction, this technique is ideal for designs that require decoration and high detail.

Versatility: The technology is suitable for a variety of materials, including cotton, polyester, blended fabrics and hard materials such as ceramics, metals and wood. This makes it extremely flexible in different application scenarios.

Durability and durability: Through thermal customization, sublimation DTF is able to push dye fibers deep into the interior, thus enhancing the washable and durable image. Printed products can maintain bright colors and clear patterns after repeated cleaning.

Environmental protection: Compared to traditional printing methods, the ink and materials used by thermal sublimation DTF are more environmentally friendly. The technology does not require the use of large amounts of water and chemicals, thus reducing pollution to the environment.

Efficient production: Sublimation DTF can be large-scale mass production, and efficient production speed. This production method can meet the market demand for rapid delivery and mass customization of products.

Low market: This technology is relatively easy to operate and does not require complex equipment and technical training. This has allowed more small businesses and individual industrial and commercial businesses to enter the market, thus driving the development and competition of the industry.

Innovative design freedom: Sublimation DTF technology allows designers to be creative and free from the shackles of traditional printing methods. Designs can include complex patterns, gradients of color and delicate details to provide customers with a unique, personalized product.

26 products found

ViewShowcase

this sublimation ink can be used to print on silk-like polyester, sports T-shirts, cycling jerseys, polyester bags, umbrella...

fcolor suitable for thermal sublimation xp15000 printer eries of thermal sublimation inks

fcolor suitable for thermal sublimation xp15000 printer eries of thermal sublimation inks

FCOLOR L8058 3D sublimation printer with 3D Sublimation Vacuum heat transfer machine for phone cases

L8058 3D sublimation heat transfer printing machine for clothing printing

DTF ink prints with bright colors, high degree of pattern printing, clear and smooth without clogging

Good ink control and absorption, Good line-sharpness and image quality Instant dry

Good ink control and absorption, Good line-sharpness and image quality Instant dry

This paper must be printed by sublimation ink, Could not use on the 100% pure cotton textile,

Good ink control and absorption, Good line-sharpness and image quality Instant dry

Great on a wide variety of hard surfaces with a sublimation-coating: coasters, jewelry, mugs, etc.

this sublimation ink can be used to print on silk-like polyester, sports T-shirts, cycling jerseys, polyester bags, umbrella...

this sublimation ink can be used to print on silk-like polyester, sports T-shirts, cycling jerseys, polyester bags, umbrella...

this sublimation ink can be used to print on silk-like polyester, sports T-shirts, cycling jerseys, polyester bags, umbrella...

this sublimation ink can be used to print on silk-like polyester, sports T-shirts, cycling jerseys, polyester bags, umbrella...

Compatible with the MBIS (Mimaki Bulk Ink System) on following Mimaki printers

Compatible with the MBIS (Mimaki Bulk Ink System) on following Mimaki printers

6 Colors Dye Sublimation Ink For Ecotank L8168 Printer

work for Epson WF-7710 7720

100% new,pre-tested

High transfer rate, Vivid Color, Environmentally safe

High transfer rate, Vivid Color, Environmentally safe

This paper must be printed by sublimation ink, Could not use on the 100% pure cotton textile,sublimation transfer paper

High resolution prints for perfect results.

Equipped with ICC curve file to achieve perfect printing effect.

Equipped with ICC curve file to achieve perfect printing effect.

6 Colors Dye Sublimation Ink For Ecotank L8168 Printer

FCOLOR professional young after-sales team

A well-trained team that has been in business for several years has solved countless after-sales problems that customers worry about

1. Technical knowledge and skills

DTF technology principle: In-depth understanding of the working principle, operation process and common problems of DTF technology.

Equipment maintenance: familiar with the structure and maintenance methods of DTF equipment, able to carry out daily maintenance and troubleshooting of equipment.

Software operation: master the use of relevant design software and printing software, and be able to guide customers to correct operations.

2. Customer service ability

Communication skills: Good communication skills, able to clearly explain problems and solutions to customers.

Problem solving ability: The ability to quickly respond to customer needs and problems, to provide effective solutions.

Patience and empathy: Be patient with customers, understand their problems, and provide considerate service.

3. Training ability

User training: Able to provide comprehensive training to customers to ensure that customers can proficiently operate DTF equipment and software.

Technical guidance: Provide continuous technical support and guidance to customers to help customers improve operational skills and productivity.

Please send your message to us

- Name

- Tel

- *Title

- *Content