- Printer

- Ink

- Consumables

- Type

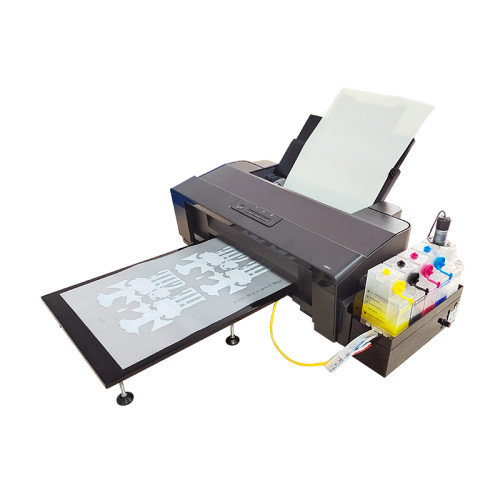

- DTF Printer

- Sublimation Printer

- Eco-solvent printer

- Card printer

- label printer

- DTF oven

- DTF hot press machine

- Applicable ink

- DTF ink

- Sublimation ink

- Textile ink

- Dye ink

- Pigment ink

- Eco-solvent ink

- Color

- 4 colors

- 6 colors

- 8 colors

- 12 colors

- Ink properties

- DTF ink

- Sublimation ink

- Textile ink

- Dye ink

- Pigment ink

- UV ink

- Eco-solvent ink

- Capacity

- 70ML

- 100ML

- 500ML

- 1000ML

- 2000ML

- 25L

- Sales attribute

- Hot product

- New product

- Spot products

- OEM

- ODM

- Application Scenario

- Garment heat transfer printing

- Garment Sublimation Printing Printing

- Garment Direct Injection Printing

- Outdoor Advertising Printing

- Graphic and image printing

- Metal/Glass Printing

- label printing

- Card printing

- Other ink

- For people

- Clothing printing processing

- Physical advertising store

- Individual/Business/Government

- Photo studio

- Packaging and printing plant

- Hospital

- Printing house

- Packaging industry

- School library

- Mechanical printing plant

- Type

- DTF film

- DTF hot melt powder

- DTF hot melt powder

- Sublimation paper

- Washing fluid

- PVC card

- label paper

- Application field

- DTF printing field

- Sublimation printing field

- Card printing field

- Label printing field

DTF

Digtal Printing One-stop slution

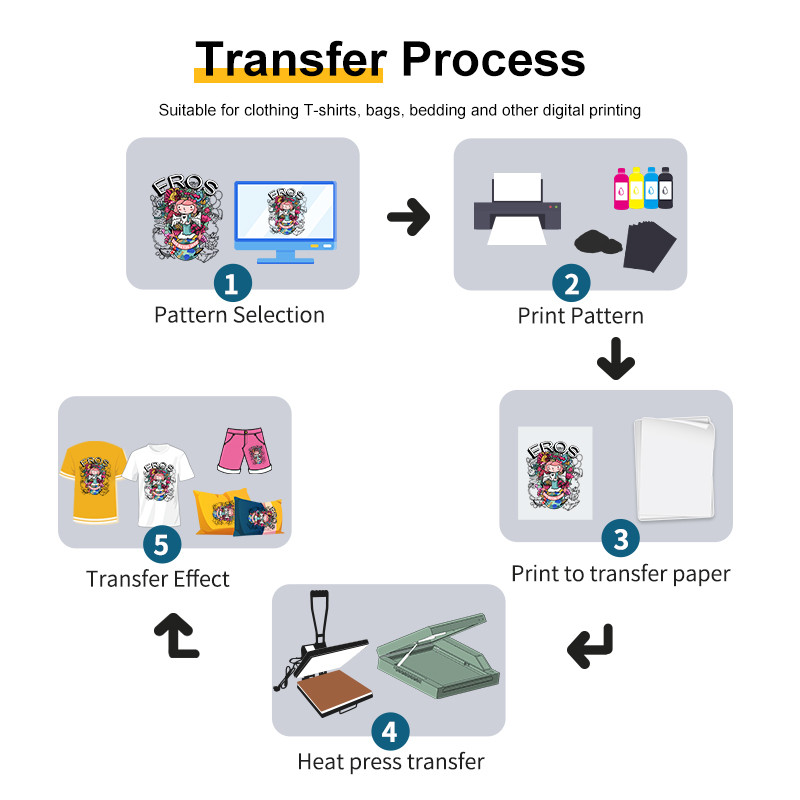

FCOLOR DTF Process introduction

Early-Stage Preparations

Design and prepare images

Image design: Create or edit images using design software such as Adobe Photoshop, Illustrator, etc.

Image processing: To ensure that the resolution and color mode of the image are suitable for printing, it is usually necessary to adjust to CMYK mode.

Print material preparation

Diaphragm preparation: Select a PET diaphragm suitable for the DTF process, usually with a thickness of 0.075-0.125mm.

Powder preparation: Select the appropriate hot melt adhesive powder, and choose different powder types according to different fabrics.

Intermediate production

Image printing

Printer Settings: Set parameters for DTF dedicated printers, including print resolution, ink type, etc.

Print image: Print the designed image onto a PET diaphragm. It is usually necessary to print the background color with white ink to ensure that the image will show clearly on dark fabrics.

Shake powder treatment

Powder: Evenly sprinkle hot melt adhesive powder on the newly printed image.

Remove excess powder: Gently shake the diaphragm to remove excess powder that does not adhere to the ink.

Hot press curing

Preheat: Preheat the hot press to the appropriate temperature (usually 160-180°C).

Hot press curing: The coated membrane is placed in a hot press for curing for about 5-10 seconds to ensure that the powder and ink are fully integrated.

After-Treatment

Cooling and separation

Cooling: Remove the cured film and leave it for a period of time to cool.

Separate the diaphragm: Gently peel off the image from the cooled diaphragm.

Transfer to fabric

Prepare the fabric: Place the fabric to be transferred flat on the hot press.

Transfer: Align the stripped image with the fabric and place it where it needs to be transferred. Hot press transfer is performed using a hot press, usually at a temperature of 150-160°C and for 10-15 seconds.

Cooling: After the transfer is completed, the fabric is removed and left to cool.

Quality inspection and post-processing

Quality check: Check whether the transferred image is complete and free of defects.

Post-treatment: If necessary, further treatment can be carried out, such as hot pressing again to enhance adhesion or other post-processing.

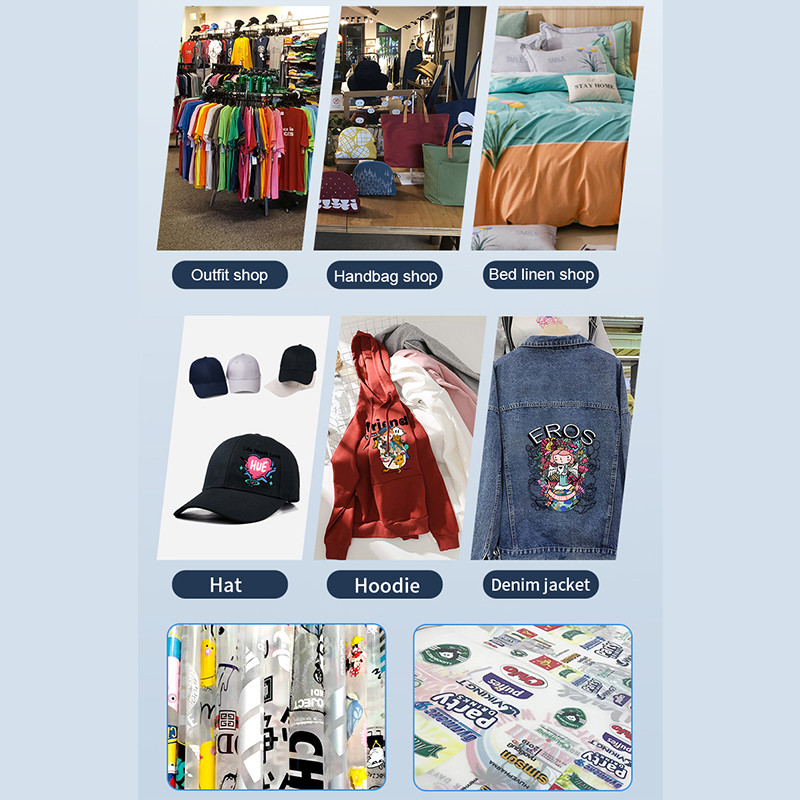

A wide range of DTF application scenarios

1. Clothing printing

DTF technology is widely used in the field of clothing printing, especially for personalized customization and small batch production. With DTF technology, design patterns can be directly transferred to a variety of fabrics, including cotton, polyester, nylon, etc. DTF printing patterns are bright in color, clear in detail, and resistant to washing and wear.

2. Home decor

DTF technology can also be used in the production of home decorations, such as pillows, tablecloths, curtains and so on. Through DTF printing, home decorations can present high-quality, personalized patterns to enhance the overall decorative effect.

3. Leather goods

DTF technology is suitable for printing all kinds of leather products, including handbags, wallets, belts, etc. DTF printing can form a strong, durable pattern on the leather surface that is not easy to fall off.

4. Gifts and crafts

DTF technology can also be used in the production of custom gifts and crafts, such as mugs, key rings, mobile phone cases, etc. With DTF printing, gifts and crafts can show a unique personality and creativity.

5. Advertising and promotional items

DTF technology is also widely used in the production of advertising and promotional goods, such as T-shirts, hats, shopping bags with the company logo. DTF printing can ensure the high-quality presentation of the pattern, enhance the brand image and publicity effect.

30 products found

ViewShowcase

DTF printer High precision nozzle printing clearer image 60cm roll to roll direct to film printer

FCOLOR improved DTF inkjet digital printing printing, more complete features, more secure digital printer

FCOLOR A3 DTF Dual XP600 Printer for T-Shirts - OEM/ODM, Wholesale Partnerships & Agent Support.

540dpi/720dpi/1440dpi(4pass,6pass,8pass)

Double Epson XP600 print heads, color and white at the same time.

Double Epson XP600 print heads, color and white at the same time.

60cm DTF powder shaker machine, combines dusting powder , shaking powder and baking in one. Simple operation, easy to use.

MAX Print Size A3+ (13x19'' )

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer

Ink Supply System for Epson xp15000, effectively increase the printing ink capacity, printer work longer, large volume printing

MAX Print Size A3+ (13x19'' )

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer

L8050 6 colors ink supply system for l8050 printing machine,support OEM,ODM

1. Product name : Mini oven

2. mini oven size : A4 A3 A3+ pet film

3. stock :YES

4. easy to handle

2. mini oven size : A4 A3 A3+ pet film

3. stock :YES

4. easy to handle

dtf powder shaker/Front and rear heating function/The net-work port speed is fast/The seven colors have a wider range

540dpi/720dpi/1440dpi(4pass,6pass,8pass)

Delivery (500ML) five-color dtf ink set and dtf cleaning fluid

Delivery (500ML) five-color dtf ink set and dtf cleaning fluid

MAX Print Size A3+ (13x19'' )

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer

MAX Print Size A3+ (13x19'' )

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer

350 DTF printer:

Weight advantage [8kg less than the double head, the current machine 35.2kg]

Print speed [2 times faster than dual-head printer]

Printing engine room [Ink truck space, more convenient equipment maintenance]

Intelligent ink kettle [white ink + waste ink automatic alarm to avoid too much waste ink and too little ink]

Weight advantage [8kg less than the double head, the current machine 35.2kg]

Print speed [2 times faster than dual-head printer]

Printing engine room [Ink truck space, more convenient equipment maintenance]

Intelligent ink kettle [white ink + waste ink automatic alarm to avoid too much waste ink and too little ink]

FCOLOR A4 L8050 DTF printer For clothing textile, supports OEM/ODM, simple operation and easy to use.

fcolor dtf remover is suitable for patterns printed by dtf printers and is suitable for various transfer media and fabrics

FCOLOR L8050 A4 DTF printing machine for clothing printing support OEM&ODM

13 inch 8 Colors DTG Printer Direct to Garment Printer Dual I3200M Printheads T-Shirt Printing Machine for Hoodies Pants

high quality White Fine Size Polyamide TPU Powder for DTF Hot Melt Adhesive Powder

The motor for DTF continuous supply can stir the ink to prevent liquid ink from settling and protect the print head

This product has strong compatibility, good printing effect, high-quality materials, high transfer rate

DTF ink prints with bright colors, high degree of pattern printing, clear and smooth without clogging

DTF ink prints with bright colors, high degree of pattern printing, clear and smooth without clogging

FCOLOR professional young after-sales team

A well-trained team that has been in business for several years has solved countless after-sales problems that customers worry about

1. Technical knowledge and skills

DTF technology principle: In-depth understanding of the working principle, operation process and common problems of DTF technology.

Equipment maintenance: familiar with the structure and maintenance methods of DTF equipment, able to carry out daily maintenance and troubleshooting of equipment.

Software operation: master the use of relevant design software and printing software, and be able to guide customers to correct operations.

2. Customer service ability

Communication skills: Good communication skills, able to clearly explain problems and solutions to customers.

Problem solving ability: The ability to quickly respond to customer needs and problems, to provide effective solutions.

Patience and empathy: Be patient with customers, understand their problems, and provide considerate service.

3. Training ability

User training: Able to provide comprehensive training to customers to ensure that customers can proficiently operate DTF equipment and software.

Technical guidance: Provide continuous technical support and guidance to customers to help customers improve operational skills and productivity.

Based on the image you provided, here is a breakdown of the content summary:

1. Easy maintenance and repair

- Provides easy-to-understand instructions and videos on how to keep your printer clean and well maintained.

- English speaking technicians are always available to help.

2. Perfect print quality

- Ensure excellent print quality using premium components such as print heads, DTF inks and PET films.

- Avoid common problems such as color inconsistency and image distortion.

- A range of printers with built-in tools and advanced software to optimize print quality.

3. Affordable consumables

- Offers competitive ink charging prices and a wide selection of consumables.

- The ink system is designed to reduce ink waste and overall cost.

4. Easy to use software

- Friendly software interface, easy to configure and use.

- Provides a convenient printing experience for beginners and professionals alike.

This summary covers the main points in the picture, please let me know if there are any parts that need to be explained in detail.

Please send your message to us

- Name

- Tel

- *Title

- *Content