Fcolor sublimation ink for epson xp15000 100ml

| Categories | Sublimation Ink |

|---|---|

| Brand | Fcolor Printer Supplies Wholesale Manufacturer |

| Model | DSUO1 |

| variety of colors | 6 colors |

| capacity | 100ml |

| Applicable technology | Thermal sublimation transfer |

| Applicable printers | xp15000 |

| Update Time | Dec 21,2024 |

Detail Information

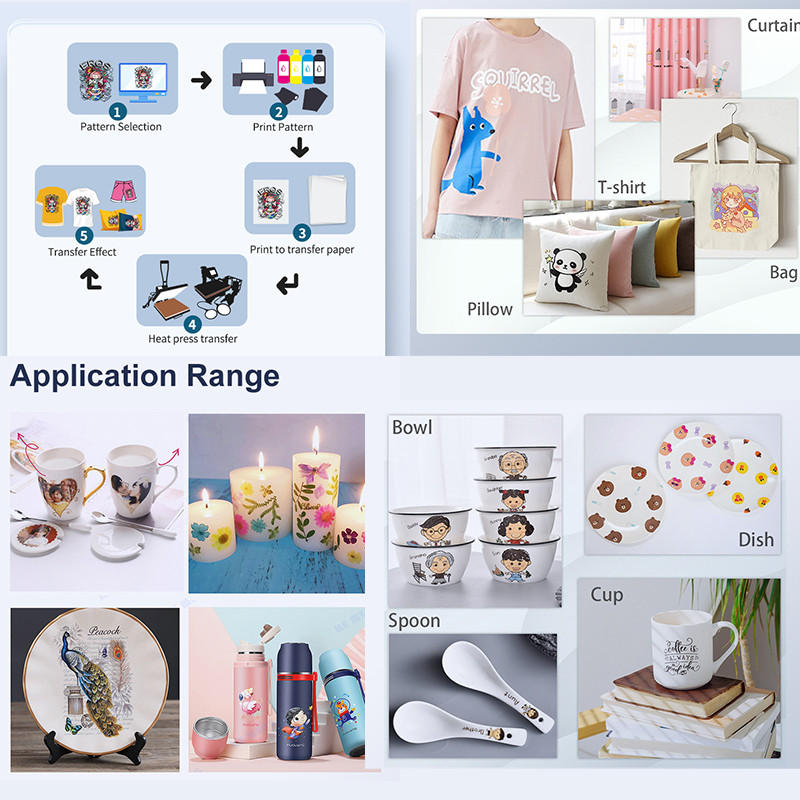

sublimation xp15000 printer eries of thermal sublimation inks

sublimation ink for xp15000

1. High quality output:

The fcolor sublimation ink is suitable for the XP15000 printer series to ensure that the printed images are colorful and clear in detail to meet the output needs of professional grade.

2. Excellent compatibility:

Designed for the XP15000 printer, it fits perfectly with the printer, ensuring a smooth printing process without plugging and without damaging the printer.

3. Quick drying:

Using advanced formulations, the ink dries quickly on the printing medium, preventing smudging and stains, and improving work efficiency.

4. Strong durability:

The printed works are resistant to water, light and fade, ensuring long-term preservation, suitable for all kinds of textiles, coasters, mouse pads and other thermal sublimation products.

5. Environmentally friendly formula:

The ink is made of environmentally friendly materials, in line with international environmental standards, safe and non-toxic, harmless to the environment and users.

6. Affordable:

Ink high concentration formula, printing volume, low cost of use, providing cost-effective printing solutions.

how to remove sublimation ink from shirt?

1. Prepare the design pattern:

Design the pattern to be transferred on the computer, paying attention to color and resolution.

2. Print pattern:

Using thermal sublimation ink and transfer paper, design patterns are printed on transfer paper through a thermal sublimation printer.

3. Prepare for transfer:

Ensure that the surface of the item to be transferred is clean, dry, and can withstand high temperatures.

4. Set up the heat transfer machine:

Preheat the heat transfer machine to the desired temperature (usually between 180°C and 200°C), set the required time (usually 30 to 60 seconds), and adjust the pressure.

5. Place the transfer paper:

Place the printed transfer paper face down on the transfer item and secure it with heat-resistant tape to prevent movement.

6. Heat transfer:

Put the transfer item into the heat transfer machine, press the platen to start the transfer, and wait for the set time to end.

7. Cool and remove paper:

After the transfer is completed, remove the item, wait for cooling, carefully tear off the transfer paper, and check the transfer effect.

Related Products

Review

- Loading...

Please send your message to us

- Name

- Tel

- *Title

- *Content

Please send your message to us

- Name

- Tel

- *Title

- *Content