DTF Printing: Money-Saving Hacks You Need to Know

DTF printing technology, with its vibrant colors and ease of use, has quickly become a popular choice in the custom printing field. However, as business volume grows, print costs have become a focal point for many users. How can you effectively control DTF printing costs while maintaining print quality? Today, Fcolor combines its extensive product experience to offer you a cost-effective and efficient DTF printing solution.

1. Control Costs from the Source: Choose the Right Consumables

DTF printing costs are largely determined by consumables, so selecting the right materials is the first step in controlling expenses.

DTF Ink: High-quality DTF ink is essential. Choose vibrant, smooth-flowing inks to minimize printhead clogging, extend printer life, and lower maintenance costs. Although high-quality ink may be slightly more expensive, its stability provides greater benefits in the long run. Additionally, choose the right type of ink, such as CMYK+white ink for colorful designs or fluorescent ink to add highlights. Avoid stocking too much ink and select the right packaging size to prevent wastage due to expired ink.

DTF Film: The quality of DTF film directly affects transfer quality and durability. Cold peel and hot peel films each have their advantages, so choose the one that fits your needs. Selecting the right thickness and type of film reduces transfer failure rates and prevents material waste.

DTF Powder: DTF powder plays a crucial role in the adhesion of the print. Choosing high-quality DTF powder, such as Fcolor's DTF hot-melt powder, ensures that designs adhere well to various fabrics, reducing rework costs due to peeling and fading.

2. Optimize the Printing Process

Besides choosing the right consumables, optimizing the printing process can significantly reduce costs.

Printer Settings: Adjust printer settings, such as resolution and ink usage, based on the design and fabric. For simpler designs, reduce the resolution to save ink while maintaining print quality.

Pre-Treatment: Pre-treat substrates, such as removing dust and grease, improve ink adhesion and reduce transfer failure rates.

Transfer Temperature and Time: Strictly control transfer temperature and time to ensure the best transfer results and prevent material waste caused by overheating or overexposure.

Post-Processing: Proper post-processing, such as cold peel or hot peel, ensures design integrity and durability, reducing the need for rework.

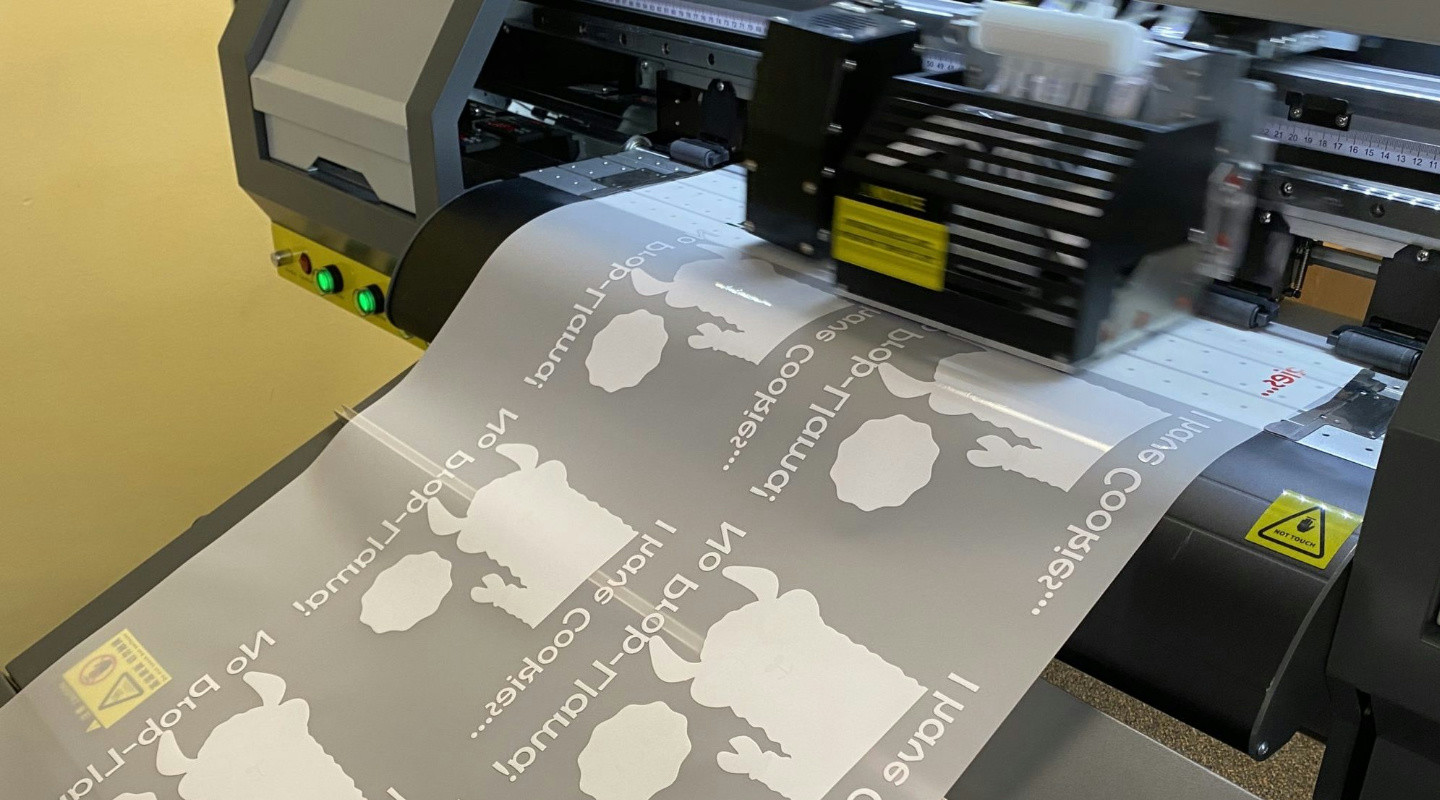

3. Case Study: Fcolor DTF Printer Kits

Fcolor offers various DTF printer kits, such as the A3-size DTF printer kit, which includes a printer, ink, film, powder, and all necessary consumables, making it easy for users to get started. Here's how we control printing costs with this kit:

Select the Right Kit: Fcolor offers different configurations of DTF printer kits. You can choose the one that fits your needs to avoid unnecessary investment.

Follow Proper Operations: Adhering strictly to the operating manual ensures optimal equipment performance, reducing failure rates and extending the printer's lifespan.

Regular Maintenance: Regularly clean printheads, ink tubes, and other components to ensure smooth printer operation, reducing the risk of failure and maintenance costs.

4. Innovative Thinking: Expand Profit Models

In addition to controlling costs, expanding profit models can help increase revenue.

Personalized Customization Services: Use DTF printing to offer personalized customization services such as custom t-shirts, phone cases, and cushions. This increases product value and boosts profit margins.

Small Batch Production: DTF printing technology is ideal for small batch production. You can adjust production schedules based on customer needs, reducing inventory buildup and mitigating risks.

Partnerships for Win-Win Situations: Partner with garment factories, gift shops, and other businesses to expand sales channels and increase market share.

DTF printing cost control is a systematic process that requires attention to consumables, printing workflows, and equipment maintenance. Fcolor is dedicated to providing high-quality DTF printing solutions, helping you stand out in a competitive market and maximize profits. If you have any questions, feel free to contact us.

DTF printer High precision nozzle printing clearer image 60cm roll to roll direct to film printer

DTF ink prints with bright colors, high degree of pattern printing, clear and smooth without clogging

high quality White Fine Size Polyamide TPU Powder for DTF Hot Melt Adhesive Powder

This product has strong compatibility, good printing effect, high-quality materials, high transfer rate