DTF Printing Troubleshooting Guide: Easy Solutions for Your Printing Challenges

DTF (Direct-to-Film) printing has quickly become a popular technology in the field of custom printing, known for its vibrant colors, detailed designs, and versatility. However, like any printing method, it comes with its own set of challenges. In this article, we will delve into common DTF printing issues and provide solutions based on Fcolor's products and expertise to help you eliminate printing problems and master DTF printing.

1. Color Issues: Achieving Your Ideal Color Match

Issue 1: Color Distortion, Not Matching the Design File

Cause: Ink quality, ICC profile, clogged printer heads, print temperature, and transfer film can all impact color accuracy.

Solution: Choose high-quality DTF ink with excellent color vibrancy and stability, such as Fcolor DTF Ink, to reduce color distortion. Use an ICC profile that matches Fcolor ink and clean the printer heads regularly. Adjust the print temperature based on the transfer material and select high-quality DTF transfer films like Fcolor DTF Film for better color fidelity.

Issue 2: Dull Colors, Lack of Vibrancy

Cause: Low ink concentration, incorrect print mode settings, insufficient transfer time, or temperature can cause dull colors.

Solution: Check the ink concentration and adjust if necessary. Use a high-quality print mode like "High Precision" or "Photo Mode." Adjust transfer time and temperature based on the material to ensure proper ink penetration and fixation.

Issue 3: Stripes or Spots in Colors

Cause: Blocked printer heads, ink supply system issues, or uneven transfer film surfaces can cause stripes or spots in prints.

Solution: Use printhead cleaning solutions to thoroughly clean blocked printer heads. Check the ink supply system to ensure smooth ink flow. Choose high-quality, smooth transfer films like Fcolor DTF Film for a flawless print.

2. Adhesion Problems: Locking in Your Designs

Issue 1: Designs Easily Peel Off, Poor Washability

Cause: Quality, amount, transfer temperature, and pressure of hot melt powder all affect the adhesion of the design.

Solution: Fcolor DTF hot melt powder offers superior adhesion and washability to enhance design durability. Adjust the amount of hot melt powder based on the complexity and size of the design. Ensure the correct transfer temperature and pressure to facilitate proper bonding with the fabric.

Issue 2: Design Edges Lifting, Not Adhering Well

Cause: High transfer temperature, uneven pressure, or poor contact between transfer film and fabric can cause lifting of design edges.

Solution: Reduce transfer temperature if it's too high. Ensure even pressure distribution during transfer. Use professional transfer equipment, such as a heat press, and ensure the Fcolor DTF Film tightly adheres to the fabric.

3. Other Common Issues: Complete Solutions for Your Printing Troubles

Issue 1: Slow Printing Speed

Solution: Optimize print settings by selecting the appropriate print mode. Consider using a high-performance DTF printer to improve printing efficiency.

Issue 2: Printer Malfunctions

Solution: Regularly maintain and clean the printer, such as cleaning the printhead and replacing DTF ink. Choose reliable printers like Fcolor DTF printers and seek technical support from Fcolor's customer service team if needed.

Issue 3: High Costs

Solution: Opt for cost-effective DTF inks, hot melt powders, and transfer films. Streamline the printing process to reduce waste. Bulk purchasing of Fcolor products offers

better pricing and more professional service.

Conclusion

We hope this guide helps you overcome common issues encountered in DTF printing. Fcolor is committed to providing high-quality DTF printing solutions. If you have any further questions, feel free to contact us for expert assistance. Choose Fcolor to start your efficient DTF printing journey!

Quantity temperature-controlled adhesive series heating system , Two output methods can be glued and AB film can be played.

digital UV DTF lamination machine - Partner with Fcolor for OEM/ODM Excellence

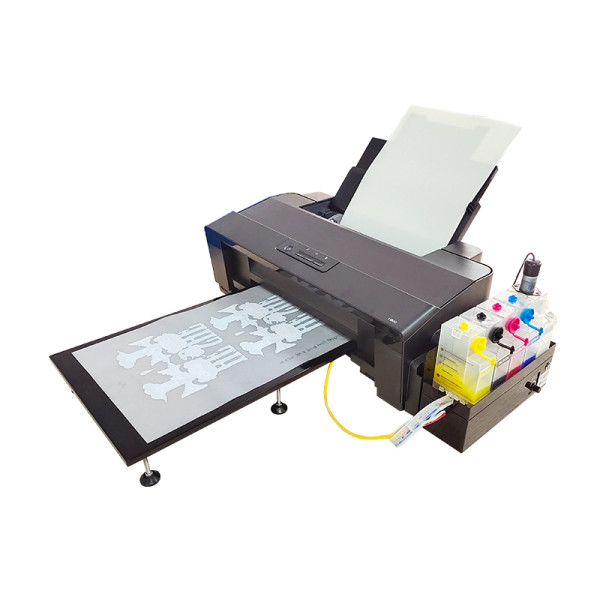

MAX Print Size A3+ (13x19'' )

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer

350 DTF printer:

Weight advantage [8kg less than the double head, the current machine 35.2kg]

Print speed [2 times faster than dual-head printer]

Printing engine room [Ink truck space, more convenient equipment maintenance]

Intelligent ink kettle [white ink + waste ink automatic alarm to avoid too much waste ink and too little ink]