How to Choose the Best DTF Film for Your Printing Needs

In the rapidly growing field of direct film printing (DTF), choosing the right DTF film is critical to achieving superior print quality and durability. At FCOLOR, we understand that the right film can make a world of difference to your printing projects. This comprehensive guide will walk you through the essential factors to consider when choosing the best DTF film for your needs.

Understanding DTF Printing and Its Benefits

Direct Printing Film (DTF) is a revolutionary method for high-quality printing on a variety of substrates, including textiles. The technology involves printing the design onto a special film, which is then transferred to the desired material using a heat press. Benefits of DTF printing include:

- Vibrant Colors: DTF printing produces vibrant, clear, vibrant colors.

- Versatility: Works well with a wide range of fabrics, including cotton, polyester, and blends.

- Durability: DTF prints are known for their permanence and resistance to cracking and fading.

- Cost-effectiveness: Lower production costs compared to traditional screen printing.

Key Factors to Consider When Selecting DTF Film

Choosing the right DTF film requires evaluating several key factors to ensure the best possible printing results. Here are the main considerations:

1. Film Thickness

The thickness of a DTF film plays a critical role in the final print quality. Thicker films generally have better durability and are less likely to tear during the transfer process. However, they may require higher heat and pressure settings. At FCOLOR, we recommend choosing a film thickness that strikes a balance between durability and ease of use.

2. Coating Quality

The coating on a DTF film affects ink adhesion and overall print quality. A high-quality coating ensures that the ink adheres securely to the film, resulting in clear, vivid prints. Look for a film with an even and smooth coating for the best results.

3. Compatibility with Inks

Not all DTF films are compatible with all types of inks. It is critical to choose a film that works well with the specific inks you are using. At FCOLOR, we offer DTF films that are compatible with a wide range of inks, ensuring flexibility and convenience for your printing projects.

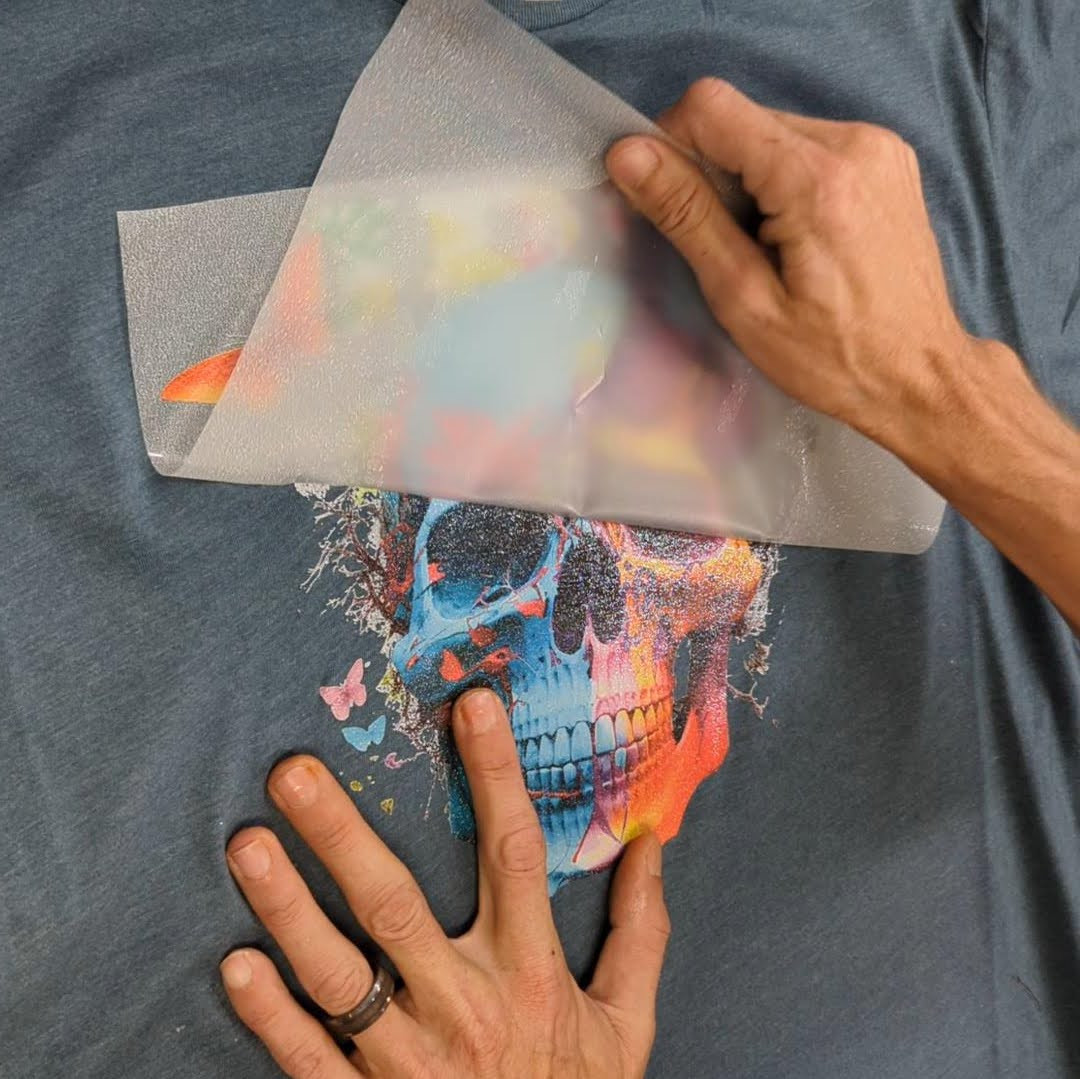

4. Release Properties

The release properties of a DTF film determine how easy it is to peel the film off after the transfer process is complete. Films with excellent release properties minimize the risk of damaging the print during the peeling process. Choose a film that peels off smoothly and easily for flawless results.

5. Heat Resistance

DTF printing requires high temperatures to transfer the pattern to the substrate. Therefore, the film must withstand high temperatures without deforming or melting. Choosing a film with high heat resistance ensures consistent and reliable performance.

6. Transfer Efficiency

Efficiently transferring the pattern from the film to the substrate is essential to achieve high-quality printing. Films with good transfer efficiency ensure that the entire pattern is accurately transferred without missing any details or flaws. At FCOLOR, our DTF films are carefully designed for optimal transfer efficiency, providing excellent results every time.

Types of DTF Films FCOLOR Offers

At FCOLOR, we offer a variety of DTF films to meet different printing needs and preferences. Here are some of our most popular products:

1. Standard DTF Films

Our standard DTF films are ideal for general-purpose printing. It has excellent color vibrancy, durability, and ease of use, making it an ideal choice for most printing applications.

2. Premium DTF Film

For those who seek superior quality and performance, our Premium DTF Film is the best choice. It features a thicker base and higher quality coating to ensure excellent printing results and longevity.

3. Specialty DTF Film

If you have specific printing requirements, our specialty DTF films can meet those needs. Whether you need a film for highly elastic fabrics or unique substrates, we have the right solution for you.

Common Mistakes to Avoid When Using DTF Film

To ensure the best results with DTF film, avoid the following common mistakes:

Using Incorrect Temperature and Pressure Settings

One of the most common mistakes when using DTF (direct-to-film) film is not following the recommended temperature and pressure settings. Each DTF film has specific requirements for heat and pressure to ensure optimal adhesion and print quality. If the temperature is too low, the adhesive may not activate properly, resulting in poor adhesion. Conversely, if the temperature is too high, it will cause the film to melt or deform, affecting the print quality.

Inadequate Curing

Curing is a critical step in the DTF process where the adhesive powder is melted to bond the print to the fabric. If this step is not done correctly, it can result in weak adhesion and premature flaking of the print. Inadequate curing is usually caused by insufficient heat exposure or insufficient curing time. To ensure proper curing, follow the recommended curing temperature and duration specified by the manufacturer.

Skipping the Powder Application Step

The application of adhesive powder is critical to the DTF process. Skipping this step or applying the powder unevenly can severely affect the adhesion and durability of the print. The adhesive powder acts as an adhesive to stick the print to the fabric during the heat pressing process. To avoid this mistake, always apply the powder evenly across the entire print pattern. Use a fine mesh screen or a dedicated powder shaker to evenly distribute the powder. After application, gently shake off any excess powder to prevent clumping or uneven bonding. Proper powder application ensures that the print adheres firmly to the fabric, thereby increasing its durability and resistance to flaking.

Conclusion

Choosing the best DTF film for your printing needs is essential to achieving high-quality and durable prints. By considering factors such as film thickness, coating quality, ink compatibility, peel performance, heat resistance, and transfer efficiency, you can make an informed decision that meets your specific requirements. At FCOLOR, we offer a wide range of DTF films designed to deliver superior performance and results. Follow our guide to properly use DTF films and avoid common mistakes to ensure the best results for your printing projects.

Explore our DTF film selection at FCOLOR and take your printing projects to the next level. With the right film and proper techniques, you can achieve stunning and long-lasting prints. If you are looking for a reliable inkjet printer and consumables manufacturer, welcome to contact us.

FCOLOR is a professional custom inkjet printer and ink manufacturer with 12 years of industry experience. Our wide range of products includes DTF printers, inkjet printers, PVC/ID cards, card printers, and label printers. In addition, we also specialize in dye sublimation and digital printing equipment, as well as a variety of consumables such as dye inks, pigment inks, sublimation inks, film inks, DTF printer inks, and ink cartridges.

Our commitment to innovation and quality ensures that our products meet the highest standards and meet the various needs of our customers. In addition to our products, we pride ourselves on providing solutions tailored to our customers' specific requirements, helping them achieve their printing goals efficiently and precisely. Whether you need advanced printing equipment or high-quality inks, FCOLOR is a trusted partner for all your printing needs

This product has strong compatibility, good printing effect, high-quality materials, high transfer rate

Cold PET Transfer Film ( DTF Film )/Hot Peel PET Transfer Film ( DTF Film )

moistureproof ,double side coating, electrostatic

Roll: 30CM 33CM 43CM 60CM

Cold PET Transfer Film ( DTF Film )

Hot Peel PET Transfer Film ( DTF Film )